info@estes-engineering.com

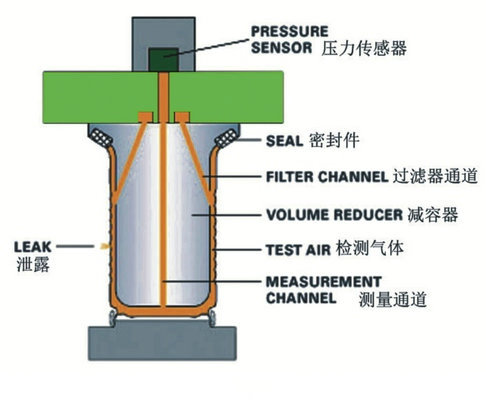

By using compressed air as the testing medium, every part of the can—including the double seam—is thoroughly tested.

By using compressed air as the testing medium, every part of the can—including the double seam—is thoroughly tested.

High sensitivity achieved by reducing can volume during the testing process using individual filling pieces

Constant testing pressure ensured by measuring filling pressure during the process

Reproducible and reliable results, even in the event of a sudden machine stop

All testing programs for different can sizes and line speeds are permanently stored

Equipped with multiple self-diagnostic features to ensure accurate testing

Short changeover times for improved production efficiency

Model | EST-JC-V40 |

Suitable Can Diameter | 52-99mm |

Suitable Can Height | 39-135mm |

Capacity | 600cans/min |

Working Heads | 40 heads |

Accuracy | Up to 0.01-0.03mm |