info@estes-engineering.com

Enhance Product Quality

Increase Production Efficiency

Lower Labor Costs

Strengthen Brand Image

The online can surface defect vision inspection system is designed to detect surface defects on cans in real time. It utilizes two or more specialized cameras each configured to inspect different areas of the can—including the inner top inner middle inner bottom outer surface and welding line.

The system employs high-contrast industrial cameras to capture detailed images of the cans. These images are transmitted to a computer via an image acquisition card. Specialized image processing software then analyzes the images to identify any defects. Defective products are accurately and automatically removed from the production line by the integrated ejection device.

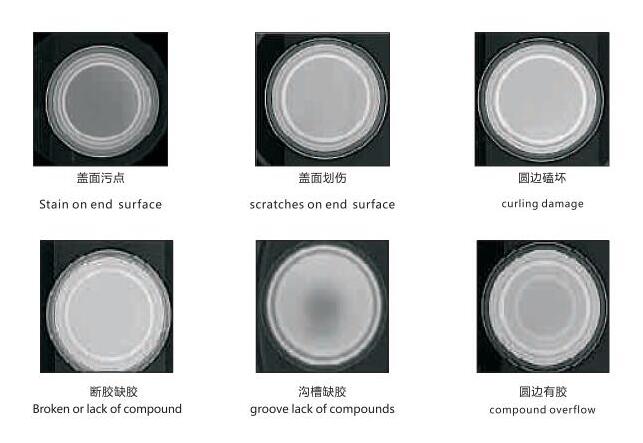

Top: Stain edge crack deformation

Inside Wall: Stain oil and grease deformation scratch coating defect inside print defect

Bottom: Stain compound residue bottom rack print bottom deformation

Outside Wall: Can upside down mixed cans barcode recognition character recognition

Welding: Welding slag oil stain can upside down miswelding welding tail burr burn mark (black spot) water stain edge crack

Model | MV-MP-G series |

Working Voltage | 220V |

Working Air Pressure | 0.4-0.6Mpa |

Power | 600W |

Working Environment | 0-50℃ |

Weight | 130kg |

Inspection Speed | 1000cans/min |