info@estes-engineering.com

The machine can be customized according to customer

specifications upon request.

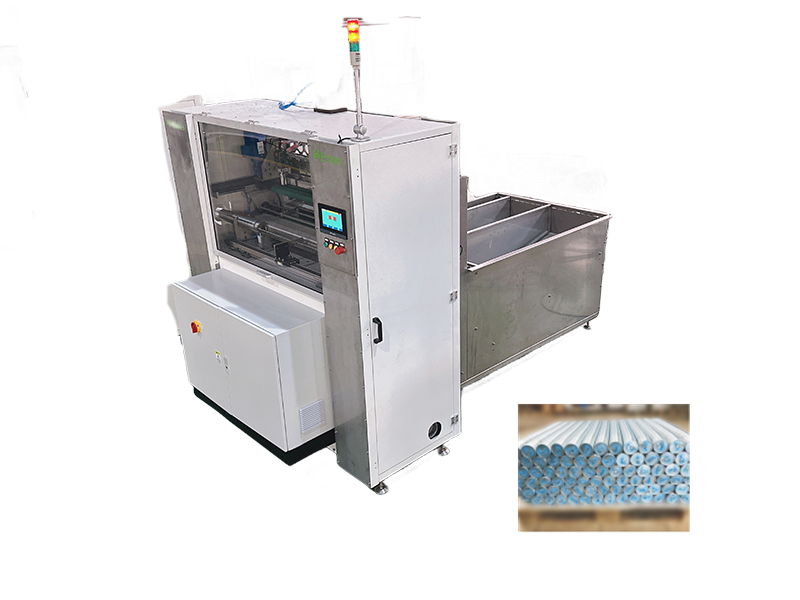

This machine is designed to automatically feed one or more seamers with unwrapped rolls of ends that were previously shrink-wrapped in plastic film.

To operate simply place the wrapped rolls horizontally into the designated stacking area. The automatic feeding system will then deliver the rolls to the film cutting station.

Film Cutting Mechanism:

The upper roller presses down and rotates to grip the roll while a hot air cutter moves horizontally between the upper and lower rollers to slice through the shrink film. Both rollers rotate simultaneously to remove the heat-shrink plastic film which is then directed into the film collecting channel below. The removed film is finally transported into a collection bag via fan-assisted airflow.

Saves labor and improves operational efficiency

Enhanced safety for operators

Gentle handling – no scratching on end rolls

End Diameter | 52-153mm |

End Type | Standard sanitary ends, easy open ends, aerosol bottoms and domes, and general line components. |

Roll Length | 250-800mm |

Capacity | 5 rolls per minutes |

Power | 5kw |

Compressed Air | 400-600L/min 6bar |

End Diameter | 52-153mm |

End Type | Standard sanitary ends, easy open ends, aerosol bottoms and domes, and general line components. |

Roll Length | 250-800mm |

Capacity | 5 rolls per minutes |

Power | 5kw |

compressed Air | 400-600L/min 6bar |