info@estes-engineering.com

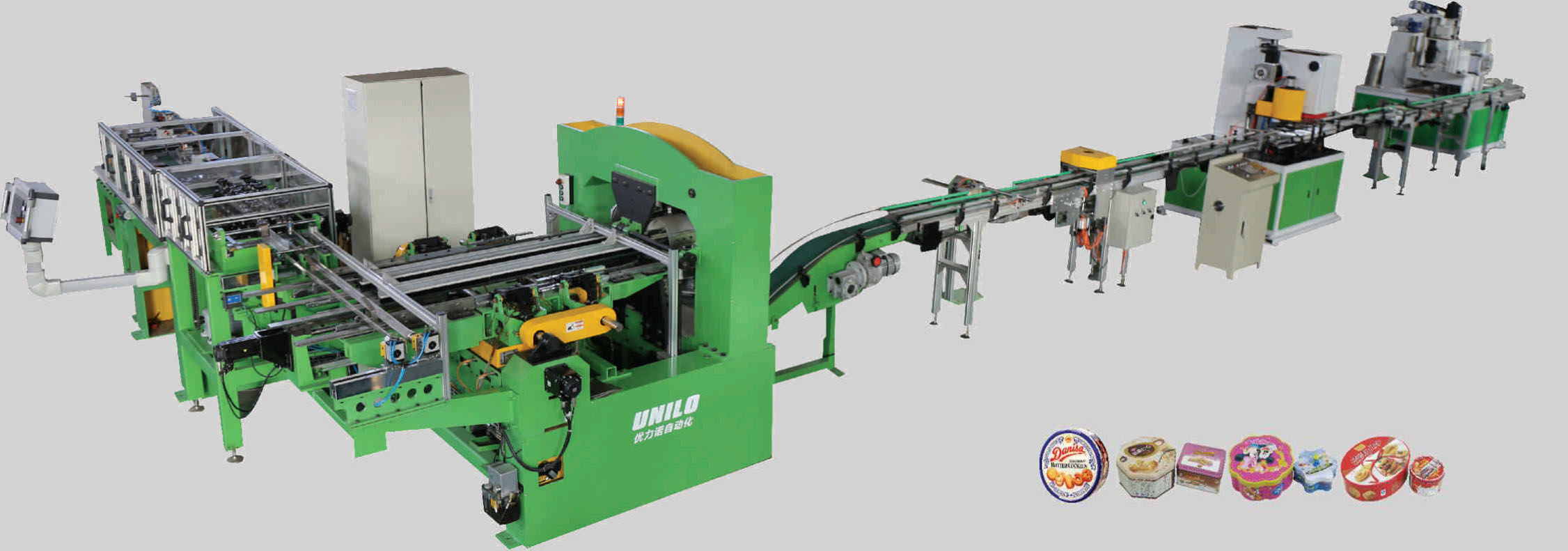

The machine features high automation, including an automatic hydraulic lifter, automatic edge cutting unit, servo-driven quick flanging and beading adjustment, servo blank feeding unit, servo quick width adjustment, edge folding unit, and quick changeover system.

The machine features high automation, including an automatic hydraulic lifter, automatic edge cutting unit, servo-driven quick flanging and beading adjustment, servo blank feeding unit, servo quick width adjustment, edge folding unit, and quick changeover system.

Digital servo adjustment

Fully automated operation

High productivity

Variable frequency speed control

Quick tool changeover

PLC control system

High-quality materials used for notching and lock seaming tools

Centralized lubrication system

Simple mechanical adjustment — no touchscreen required; single-action control

Pneumatic clutch with manual debugging function

Double sheet detection system

Model | ACBM200 | ACBM300-1 | ACBM300-2 |

Can size:Round can | φ65mm~φ190mm | φ50mm~φ300mm | φl00mm~φ300mm |

Square Can | 70x70 ~ 140x140mm | 100x100 ~ 230x230 mm | 100x100 ~ 230x230mm |

Can Height | 50mm 〜320mm | 50mm〜320mm | 50mm 〜320mm |

Tinplate Thickness | 0.16mm~0.38mm | 0.16mm 〜0.38mm | 0.16mm~0.38mm |

Capacity | 22 to 35cpm | 22 to 30cpm | 22 to 30cpm |

Power | 15kw | 15kw | 15kw |

Air Consumption | 0.15 m³/min | 0.15m³/min | 0.15m³/min |

Dimension | 5500 x 2700 x 1600 mm | 6500 x 2700 x 1800mm | 6500 x 2700 x 1800mm |

Net weight | 5.3T | 6.5T | 6.5T |